Hot New Products Ultrasonic Jet Mill - High Hardness Materials Jet Mill – Qiangdi

Hot New Products Ultrasonic Jet Mill - High Hardness Materials Jet Mill – Qiangdi Detail:

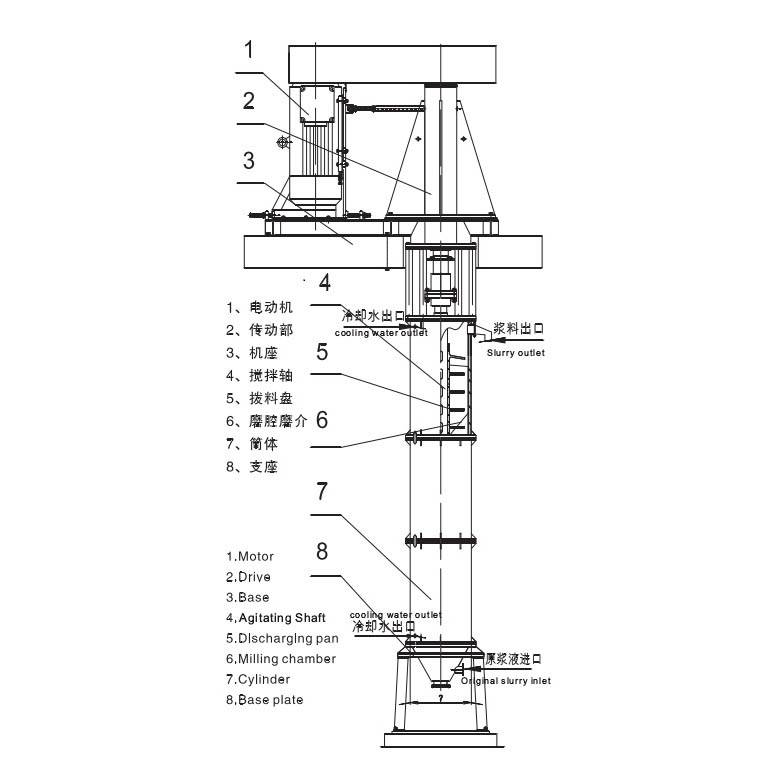

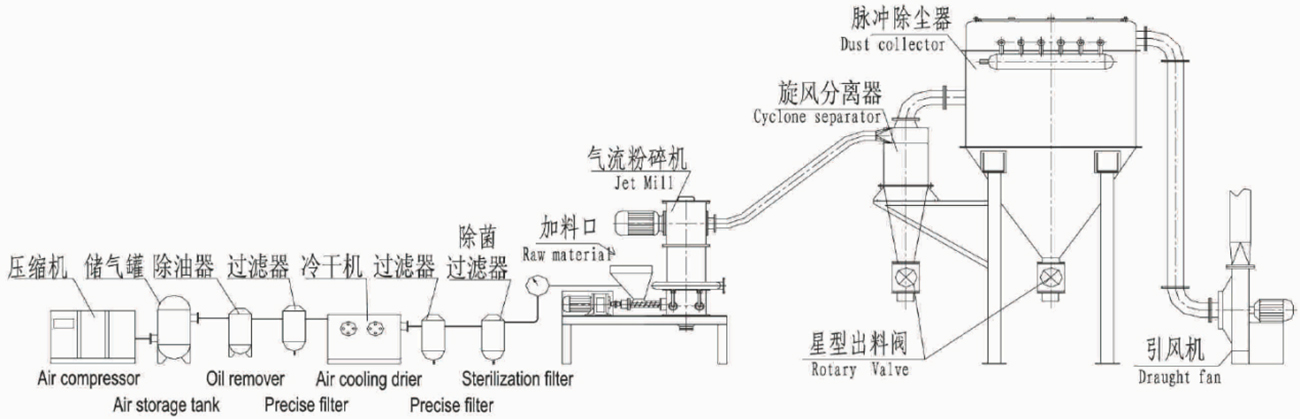

The Fluidized-bed Jet mill is actually such a device that using the high speed air flow to perform the dry-type superfine pulverizing. Driven by compressed air, raw material is accelerated to the crossing of four nozzles to be impacted and grinded by upward flowing air to the grinding zone, influenced by centrifugal force and air flow, powder up to grading wheel will be separated and collected(the bigger the particles is , the stronger the centrifugal force is; The fine particles that meet size requirement will enter the grading wheel and flow into the cyclone separator and get collected by the collector. );other powder swirls back to milling chamber for further milling processing.

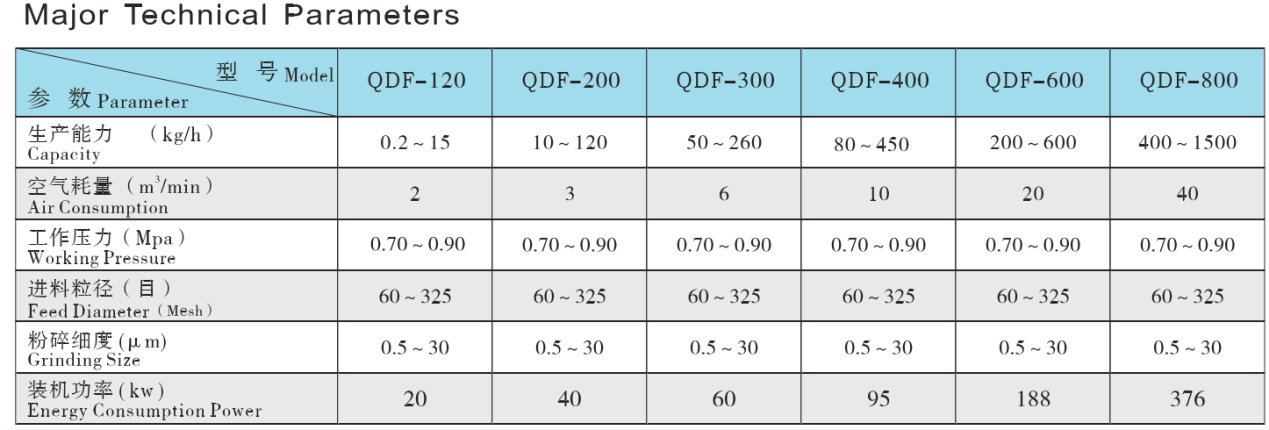

Notes: Compressed air consumption from 2 m3/min up to 40 m3/min. Production capacity depend on specific characters of your material, and can be tested in our test stations. Data of production capacity and product fineness in this sheet are just for your reference. Different materials have different characteristics, and then one model of jet mill will give different production performance for different material. Please contact me for tailored technical proposal or trials with your material.

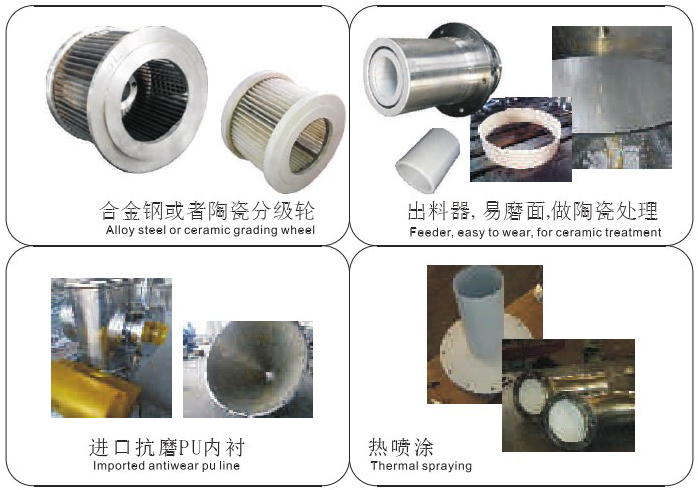

1.Precision ceramic coatings, 100% eliminate the iron pollution from material classification process to assure the purity of the products. Especially suitable for iron content requirements of the electronic materials, such as cobalt high acid, lithium manganese acid, lithium iron phosphate, Ternary Material, lithium carbonate and Acid lithium nickel and cobalt etc battery cathode material.

2. No rise in temperature: The temperature will not increase as the materials are pulverized under the working conditions of pneumatic expansion and the temperature in the milling cavity is kept normal.

3.Endurance: Applied to materials with Mohs Hardness below Grade 9. since the milling effect only involves the impact and collision among the grains rather than the collision with the wall .

The flow chart is standard milling processing,and can be adjusted for customers.

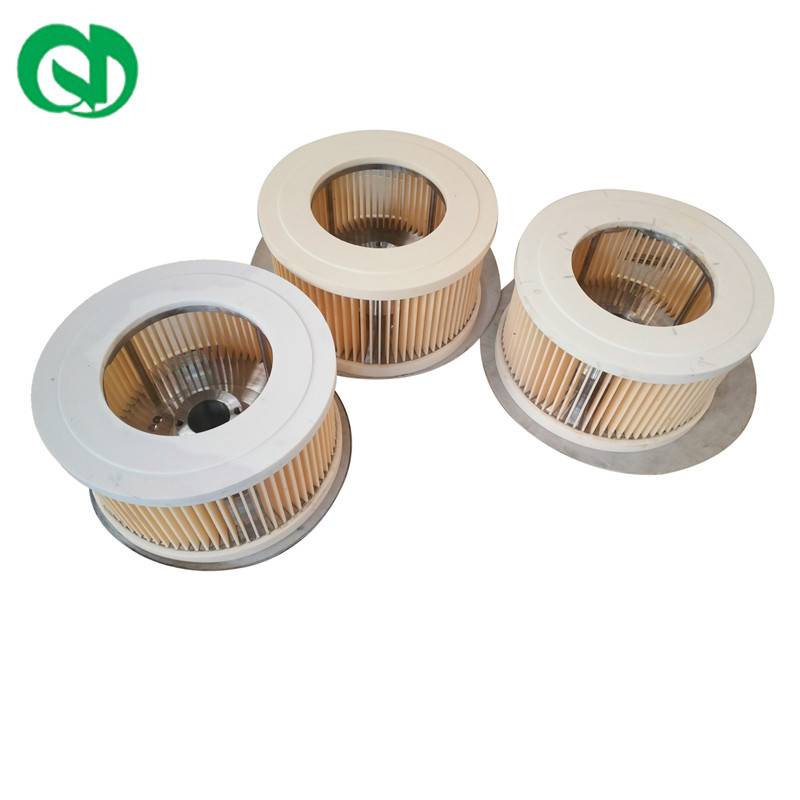

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins during the market competition by its superior quality also as provides extra comprehensive and exceptional service for consumers to let them turn into significant winner. The pursue of the business, is definitely the clients' gratification for Hot New Products Ultrasonic Jet Mill - High Hardness Materials Jet Mill – Qiangdi , The product will supply to all over the world, such as: Swiss, America, Tunisia, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.