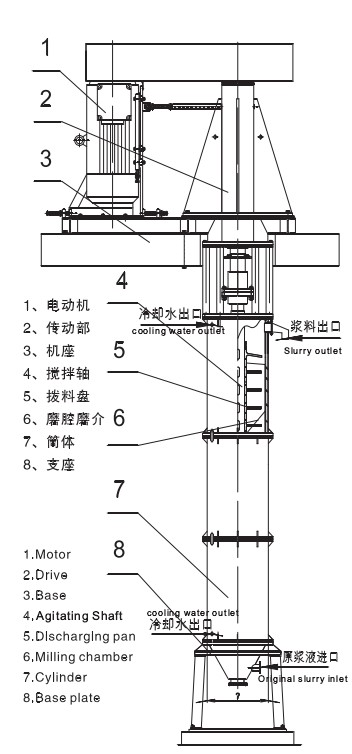

Hot Selling for Grinding Milling Machine Portable - LSM Vertical Wet Stirring Mill – Qiangdi

Hot Selling for Grinding Milling Machine Portable - LSM Vertical Wet Stirring Mill – Qiangdi Detail:

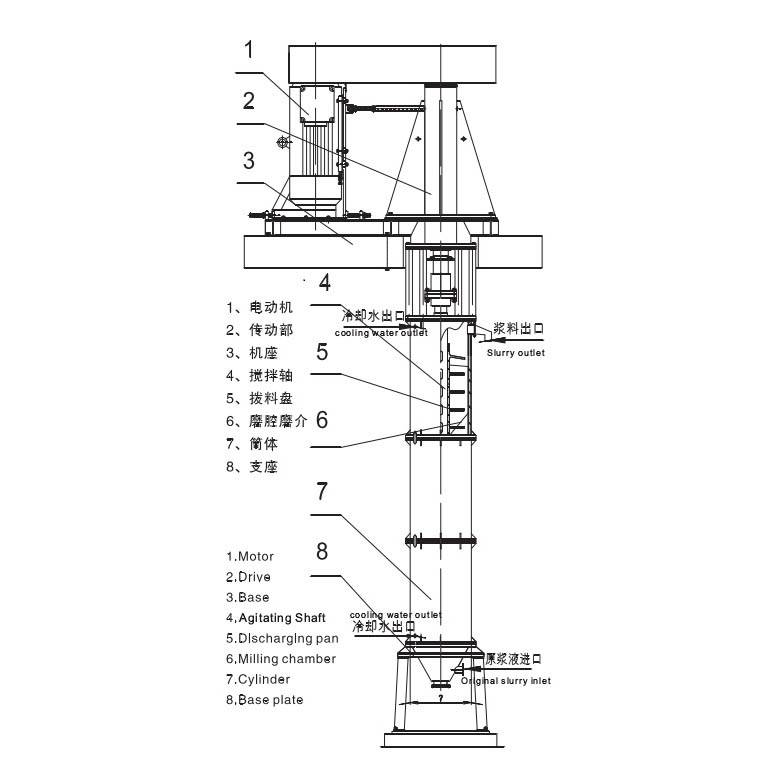

1 .LSM mixing mill absorbs the equipment characteristics of grinding, sanding, tower grinding and so on. It has the advantages of high efficiency, low noise, large processing capacity and convenient operation and maintenance.

2.when the feed size is 325 mesh, after two times of grinding can reach more than -2 Nm m95% (average particle size of 0.6 μm below).

3.you can superfine grinding, but also get excellent flow state pulp.

4. grinding cylinder grinding disc using wear-resistant materials and high hardness wear-resistant alloy materials, equipment, long service life.

5.the use of grinding media wear, particle size ratio of science, in the grinding process, no iron pollution, does not affect the product whiteness.

6.use a wet grinding mill can be continuous operation, independent of a product grinding, or can be repeated cycle feed to complete two or more products grinding.

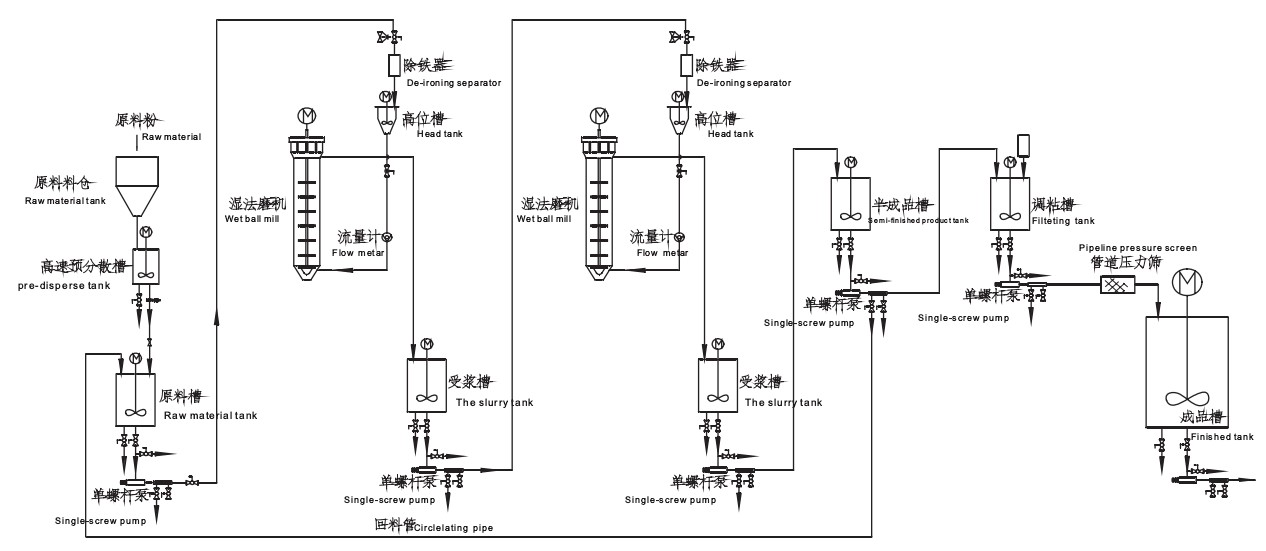

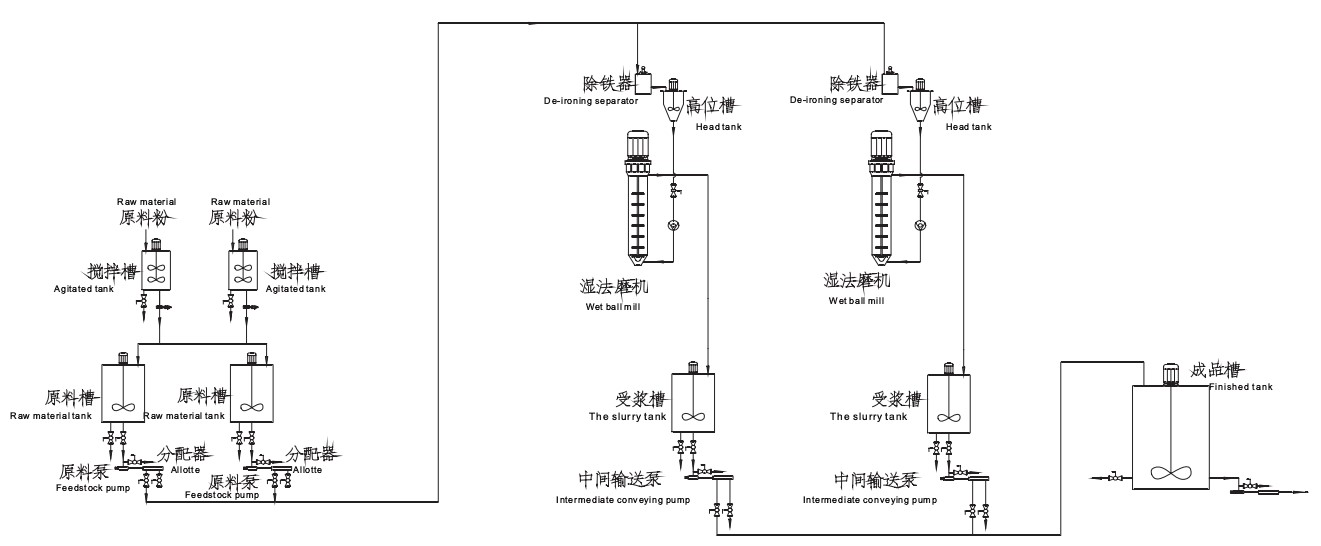

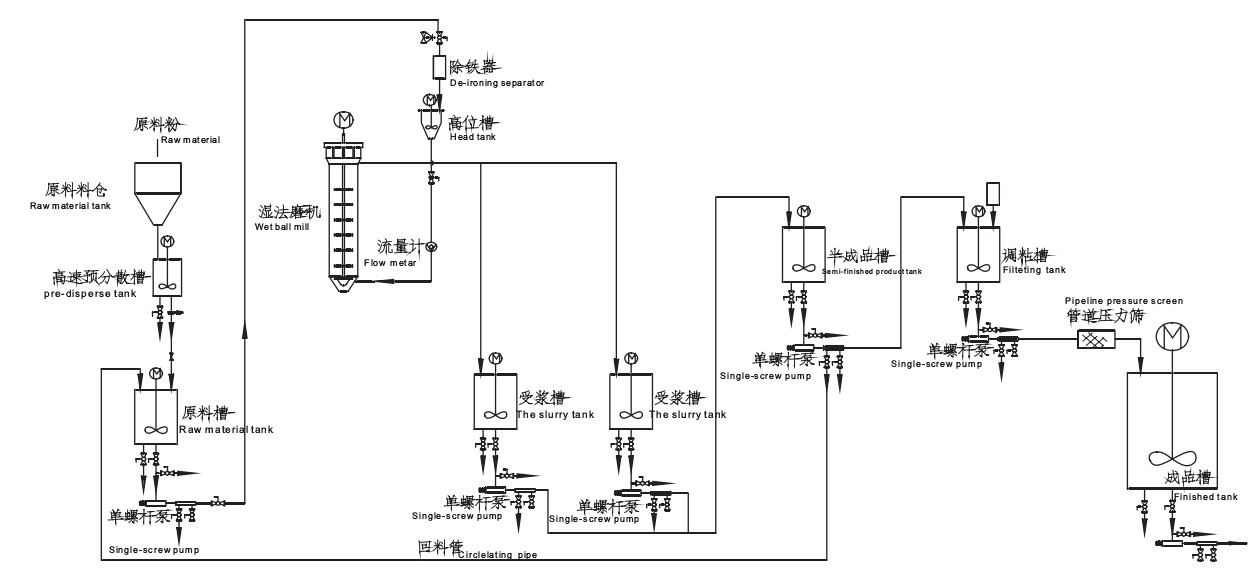

The following processes are for reference only and can be designed according to customer fineness and capacity requirements.

(1) One set Wet Ball mill flowchart

(2) Two sets in series flowchart

(3) Two sets in parallel flowchart

Product detail pictures:

Related Product Guide:

With this motto in mind, we've come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Hot Selling for Grinding Milling Machine Portable - LSM Vertical Wet Stirring Mill – Qiangdi , The product will supply to all over the world, such as: Oman, Vancouver, Rwanda, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to provide customers with high quality products, provide high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.