Hot Selling for Pulverizing Machine - Jet Micron Grader For Sorting – Qiangdi

Hot Selling for Pulverizing Machine - Jet Micron Grader For Sorting – Qiangdi Detail:

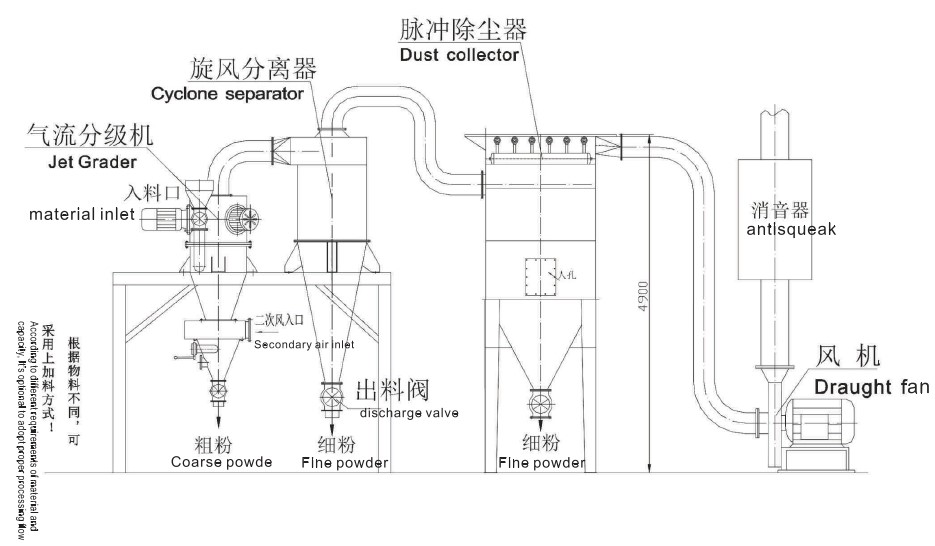

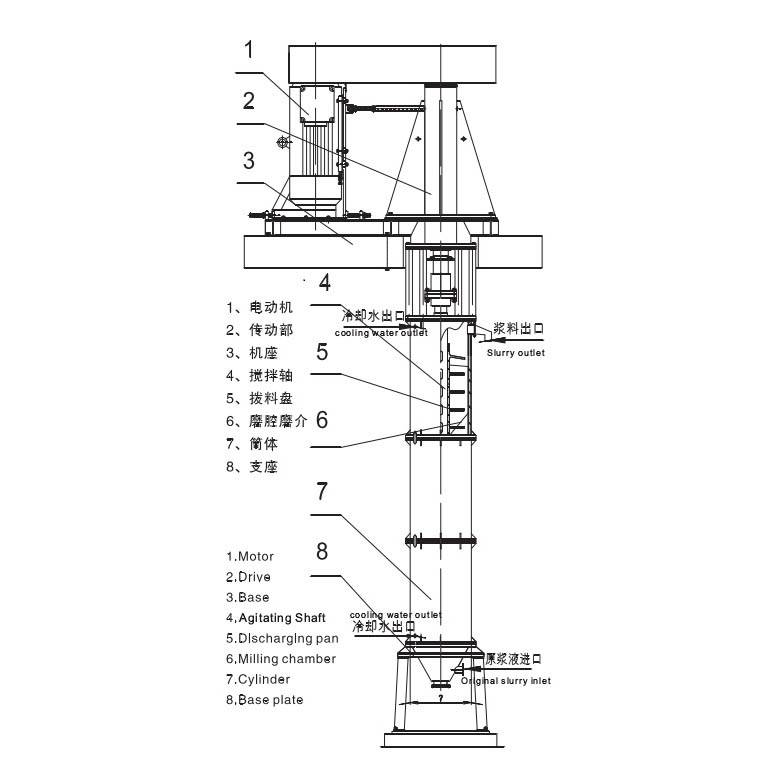

The turbine grader, as a forced centrifugal grader with secondary air entry and horizontal grading rotator is composed of grading rotator, guide vane rectifier and screw feeder. The materials are fed through the upper cartridge, and the grains will be sieved and well distributed by the incoming air,which brings the grain to the grading zone. The centrifugal force produced by the fast rotation of grading rotator together with the centripetal force produced by the pneumatic adhesion both act on the grading grains. When the centrifugal force on the grain is greater than the centripetal force, the coarser grains above the grading range will be swirled down along the container wall. The secondary air will be rectified to uniform cyclone through the guide vane and separate the thinner grains from the coarserones. The separated coarser grains will be blown out from the discharge port. The thinner grains will come to cyclone separator and collector, whereas the purified air will be vented outside from the draft.

1 .Compatible with a variety of dry type powder mill machinery (jet mill, ball mill,Raymond mill) to form a closed circuit.

2. Applied to the fine classifying of dry micron-grade products like ball, flake, needle particles and particles of different density.

3. The latest design classification rotor is used, which is a significant improvement in classifying particle size compared to former generation product, with advantages like high-precision grading and adjustable particle size and very convenient varieties replacement. vertical grading turbine device with low rotating speed, resistance to wear and low system power.

4. controlling system is automatic, running condition is displayed real time, operation is very easy.

5. system is running under negative pressure, dust emissions is less than 40mg/m, equipment noise is no higher than 60db(A)by adopting noise damping measurement.

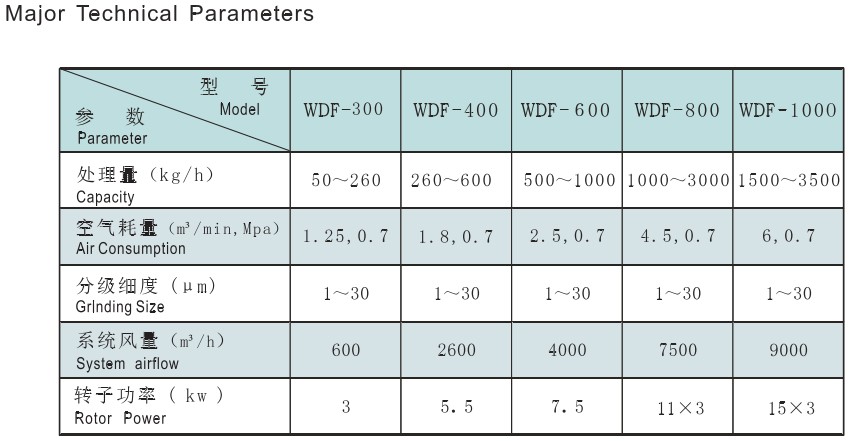

Design different process flow according to material and capacity

Product detail pictures:

Related Product Guide:

With our great management, potent technical capability and strict excellent handle procedure, we continue on to provide our customers with reputable top quality, reasonable selling prices and great providers. We purpose at becoming amongst your most trusted partners and earning your satisfaction for Hot Selling for Pulverizing Machine - Jet Micron Grader For Sorting – Qiangdi , The product will supply to all over the world, such as: Nigeria, belarus, Cairo, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.