Are you having trouble finding a reliable supplier for your powder processing needs? Worried that the Jet Mill you buy might not meet your quality standards, fit your budget, or keep up with your production? With so many options out there, it can be really confusing to know which company to trust.

Knowing what makes a good Jet Mill supplier, how to check their quality, and why the right manufacturer matters can save you a lot of time, money, and stress. Once you understand these key points, picking the right partner becomes much easier.

Why Picking the Right Jet Mill Companies Suppliers Matters

Choosing the right Jet Mill supplier is about much more than just buying a machine. It directly impacts your production efficiency, product quality, and long-term costs. Picking the wrong supplier can lead to downtime, inconsistent results, and extra expenses, while the right partner helps your operations run smoothly and reliably.

Cost-effectiveness

A trustworthy Jet Mill supplier helps you save money over time. High-quality machines with wear-resistant parts last longer, require less maintenance, and reduce frequent replacements. For example, a mid-size chemical manufacturer in India switched to a Jet Mill with advanced wear-resistant components and reported a 15% drop in maintenance costs within the first year. Reliable suppliers also help minimize downtime, keeping your production line running efficiently and avoiding costly delays.

Quality assurance

The quality of a Jet Mill directly affects powder fineness, uniformity, and purity, which are critical for pharmaceutical, chemical, and food products. Poor-quality machines can produce inconsistent powders, causing wasted materials and failed batches. At Kunshan Qiangdi, each Jet Mill goes through multi-stage inspections including material testing, performance verification, and environmental compliance. Companies that choose quality-focused suppliers often see improved yield, better product consistency, and higher customer satisfaction.

Customization options

Different industries have different processing needs. A good Jet Mill supplier can provide customized solutions to match your requirements. For instance, pharmaceutical companies may need GMP/FDA-compliant Jet Mills, while food or chemical industries may require stainless steel, easy-clean designs, or explosion-proof systems. A chemical company in Germany reported a 20% increase in production efficiency after using a custom-designed fluidized-bed Jet Mill tailored for their specific material. Choosing a supplier that can adapt machines to your needs ensures maximum efficiency, safety, and product quality.

Evaluating Jet Mill Quality

For any business buying a Jet Mill, quality is the factor that matters most. A high-quality Jet Mill doesn’t just grind powders—it ensures consistent particle size, minimizes contamination, and keeps your production running smoothly. Here’s what to focus on:

➣ Consistent Particle Size: Uniform particle size is critical because even small variations can affect the performance of your final product. Whether you are producing pharmaceuticals, chemicals, or food powders, a Jet Mill that delivers precise fineness ensures product reliability and customer satisfaction.

➣ Contamination Control: Purity is essential, especially for pharmaceutical or food-grade powders. A well-designed Jet Mill reduces the risk of contamination during processing, helping you meet strict safety and regulatory standards.

➣ Materials and Build: Look for mills made from durable, corrosion-resistant materials such as stainless steel or specialized alloys. These materials extend the machine’s lifespan and are essential for applications that require high hygiene standards.

➣ Precision and Performance: High-quality Jet Mills offer adjustable fineness and stable operation with minimal vibration. Precision engineering ensures that your production is efficient and predictable, reducing downtime and maintenance costs.

➣ Quality Certifications: Reputable manufacturers often hold ISO9001:2008, GMP, or FDA certifications. These certifications demonstrate that the company follows strict quality management procedures in both design and production.

At Kunshan Qiangdi Grinding Equipment Co., Ltd., we maintain rigorous quality checks. Every Jet Mill goes through multi-stage inspections, including raw material testing, performance verification, and environmental compliance checks. Our engineers, many with over 20 years of experience, ensure that each machine meets international standards and the specific requirements of our customers. Choosing a supplier with strict quality control reduces the risk of production problems and ensures consistent, high-quality results every time.

Right Jet Mill Company Gives You More Than Just a Machine

Choosing the right Jet Mill company isn’t just about buying equipment—it’s about finding a partner who supports your production every step of the way. A good manufacturer offers a wide range of advantages that make your investment more valuable and reliable.

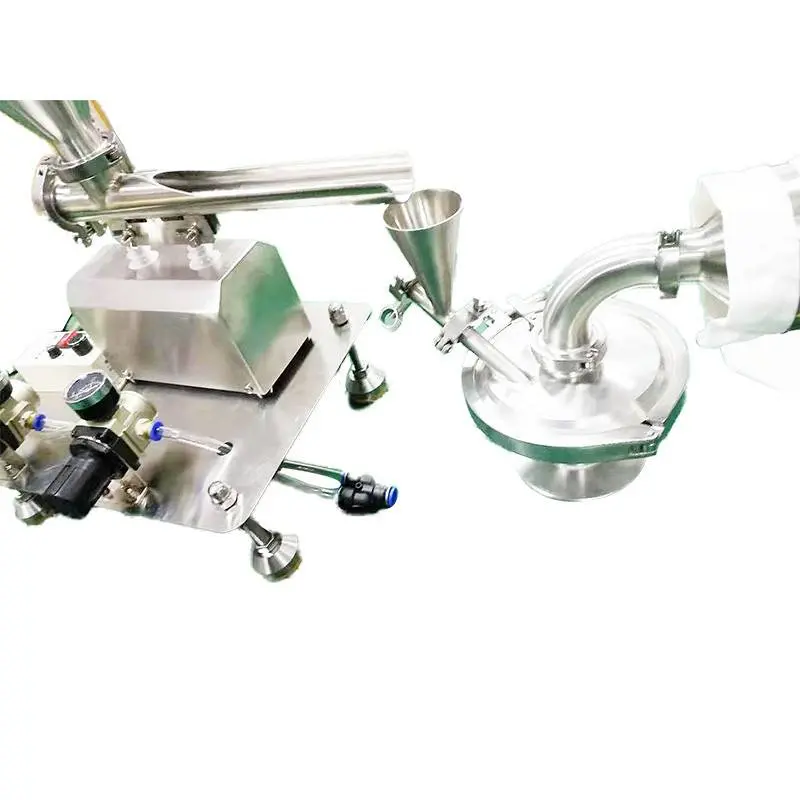

➣ Customization: Every production line is different, and the right Jet Mill company can design machines to fit your specific needs. For example, we can build explosion-proof jet mills for hazardous materials, environmental pesticide mixing systems for safer processing, or vertical wet stirring mills for specialized wet grinding applications. These custom solutions ensure your equipment works perfectly with your materials and production goals.

➣ Technical support: Our team of engineers, each with over 20 years of experience, provides expert guidance on installation, operation, and maintenance. From helping you choose the right model to solving operational challenges, we make sure your Jet Mill performs at its best.

➣ Production capacity and flexibility: As a private enterprise, we can adjust our production schedules to meet urgent orders or large-scale projects without compromising quality. For example, a client needing 5 high-end jet mills in just two months received full delivery on time thanks to our flexible production system.

➣ Pricing and value: We offer competitive pricing without cutting corners on quality. By optimizing production processes and reducing overhead costs, we deliver cost-effective solutions that fit your budget while providing long-term reliability.

➣ After-sales service: Our support doesn’t stop after delivery. Quick response times for repairs, spare parts, and troubleshooting help you avoid costly downtime and keep your production running smoothly.

➣ Performance support and model selection: Choosing the right Jet Mill model is critical. We help you select equipment based on material type, particle size requirements, production volume, and industry standards such as GMP or FDA compliance. This ensures your machine meets your exact processing needs from day one.

By partnering with a company like Qiangdi, you get more than just a Jet Mill—you gain a reliable, innovative partner committed to quality, efficiency, and your long-term business success.

Conclusion

Selecting the right Jet Mill supplier is critical for achieving efficient, reliable, and high-quality powder processing. By focusing on quality, customization options, technical support, and a strong track record, you can ensure your investment pays off.

When you work with a trusted Jet Mill manufacturer, you not only get a machine—you gain a partner dedicated to your production success. So take your time, evaluate suppliers carefully, and choose a Jet Mill company that meets your business needs.

Post time: Oct-24-2025